Let’s have a moment of silence for the hydraulic Atlas. The parkour-loving, backflipping, occasionally clumsy R&D marvel that dominated our dreams and YouTube feeds, like a particularly persistent earworm, has been officially retired. But before we could even get misty-eyed, Boston Dynamics, ever the showman, didn’t just pull the sheet off; they practically drop-kicked its successor onto the world stage. And it’s immediately clear this is a different beast entirely. This new, all-electric Atlas didn’t come to do dance-offs. It came to work.

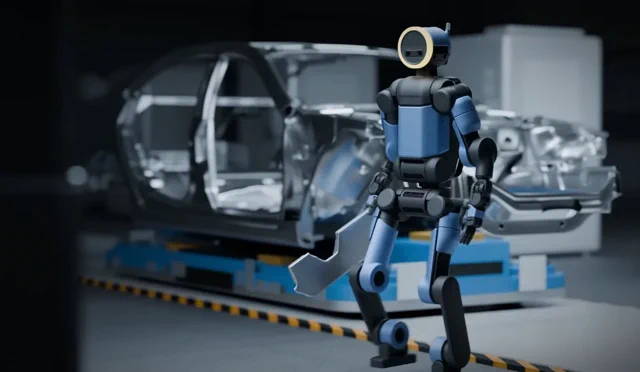

Forget the human mimicry. While other humanoids are busy trying to walk and wave with an eerily, almost-too-human grace, the new Atlas leans into its robotic nature with unapologetic zeal. It stands up like a creature from a sci-fi epic, its joints spinning a full 360 degrees in ways that would make a seasoned yoga instructor weep openly. This isn’t a design flaw; it’s the entire, glorious point. This, my friends, is the industrial GigaChad, forged for efficiency, not familiarity. It’s here to leverage its inherent robot capabilities, not to cosplay as a human warehouse worker struggling through a Monday morning.

Not Your Father’s Parkour Robot

The most significant seismic shift here is undoubtedly under the hood. The loud, complex hydraulics are gone, banished to the annals of robot history, replaced by a sleek, powerful, all-electric system. This transition unlocks a level of strength and motion that is frankly unnerving and deeply, deeply impressive. The robot is engineered to be stronger, more nimble, and possess a broader range of motion than any squishy human could ever hope to achieve.

This design philosophy is about augmenting human labour, not merely replacing it. Standing a towering 6ft 3in (1.9 metres) tall with a formidable 7ft 7in (2.3-metre) reach, Atlas can seamlessly integrate into our existing spaces. But its real value, its true calling, lies in doing the things we can’t—or, more accurately, shouldn’t. It can repeatedly lift 30 kg (66 lbs) without a single whinge to HR about ergonomic strain and operates stoically in temperatures from a frigid -20°C to a sweltering 40°C. It’s less of a coworker and more of a tireless, superhuman colleague, ready to tackle the muck and the mire without a second thought.

The new Atlas moves with a fluid, otherworldly grace that is optimised for the task at hand, not for looking vaguely human. Its head is a minimalist light ring and sensor array, and its three-fingered grippers look more like powerful industrial tools than anything you’d shake hands with. This is form following function in its most unblinkingly brutal and logical conclusion, a masterclass in robotic pragmatism.

Built for the Grind, Not the ‘Gram

Boston Dynamics has clearly spent the last five years taking copious notes from deploying over 2,000 of its Spot and Stretch robots in the unforgiving crucible of the real world. The enterprise Atlas is positively brimming with features that scream practicality, not fleeting virality.

This robot is explicitly designed for the relentless, unforgiving pace of modern logistics and manufacturing. Its key features read like a factory manager’s most fervent wish list:

- Continuous Operation: A four-hour battery life is respectable, but the ability to autonomously walk over to a station and swap its own battery in under three minutes? That, my friends, is a bona fide game-changer. This enables true 24/7 operation with minimal human intervention, keeping the gears grinding around the clock.

- Industrial-Grade Durability: With an IP67 rating, Atlas is dust-tight and can be hosed down for cleaning without batting a metallic eyelid. This is a machine built for the grime, the grit, and the general industrial mayhem of the factory floor.

- Field Serviceability: Complexity, as any seasoned engineer will tell you, is the sworn enemy of uptime. Boston Dynamics has cleverly limited the number of motors and made all limbs field-replaceable in under five minutes. No need to ship your six-foot-two robotic titan back to the manufacturer for a busted arm; a quick fix and it’s back in the fray.

Crucially, Atlas is designed to integrate seamlessly into existing facilities without the need for costly, disruptive retrofits. It works with standard 110V or 220V power and employs an onboard safety system that allows it to operate without cumbersome fences, pausing automatically when a person gets too close. It’s designed to be an active, contributing participant in a busy workplace, not a caged-off exhibit to be gawked at.

The Brains Behind the Brawn

A powerful body, no matter how impeccably engineered, is utterly useless without a sophisticated mind to guide it. Atlas is powered by the very latest in AI and machine learning, all managed through the company’s Orbit fleet management platform. This isn’t about programming a single robot; it’s about orchestrating an entire, intelligent fleet.

Operators can effortlessly assign tasks, monitor performance with eagle-eyed precision, and integrate Atlas with existing Warehouse Management Systems (WMS) or Manufacturing Execution Systems (MES). According to Boston Dynamics, Atlas can be customised for a new application in less than a day, and once one robot learns a task, that skill can be deployed to the entire fleet instantly. Talk about efficiency!

To accelerate this learning curve, the company is deepening its already formidable partnership with DeepMind. The goal is to supercharge Atlas’s ability to learn new tasks, understand the nuanced context of its environment, and adapt on the fly with a truly astonishing degree of autonomy. While it can work independently, humans remain firmly in the loop, able to take manual control via a VR headset or tablet when the situation demands it.

The Hyundai Seal of Approval

Perhaps the most telling sign that Atlas is truly ready for prime time, ready to step out of the lab and into the relentless real world, is the deep involvement of its parent company, Hyundai. The automotive giant isn’t just a benevolent financial backer; it’s the first, and arguably most important, customer. Hyundai is already planning to deploy fleets of Atlas robots in its Robotics Metaplant Application Center (RMAC) in 2026.

More importantly, Hyundai is building a brand-new robotics factory specifically to produce thousands of Atlas robots per year. This, dear readers, is the kind of unwavering commitment that propels a product from a promising prototype to a market-defining, industry-shaking force. Boston Dynamics is supremely confident in the numbers, projecting that most customers will see a return on their investment within the first two years. That’s not just good business; that’s smashing business.

Atlas has officially grown up. It has traded its show-stopping backflips for billable hours, its viral stunts for value-added tasks that will reshape industries. This robot isn’t trying to be your friend; it’s here to be the most brutally efficient, relentlessly reliable, and utterly tireless employee you’ve ever had. The industrial revolution is getting a serious second wind, and it moves with the uncanny, unstoppable, and frankly, rather intimidating grace of an electric GigaChad.