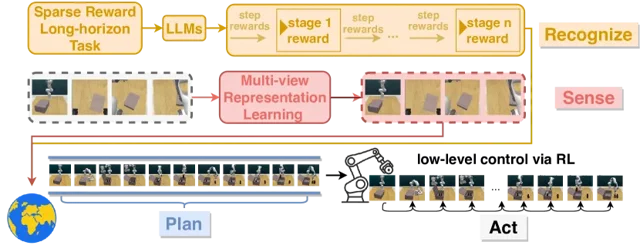

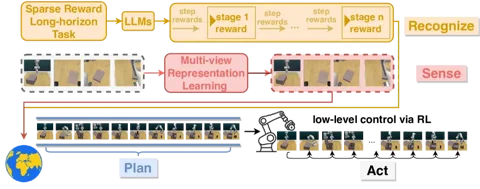

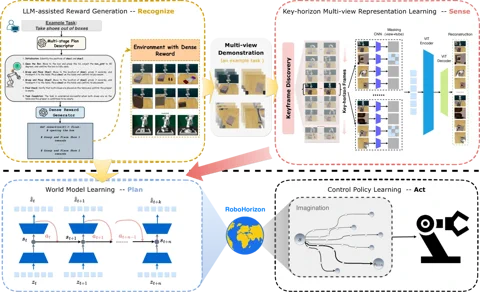

In a development that should make Swedish flat-pack furniture designers nervously eye their Allen keys, researchers have unveiled RoboHorizon, an ingenious new AI framework poised to revolutionise a robot’s knack for tackling those fiendishly complex, multi-step tasks. At its heart, this system brilliantly co-opts a Large Language Model (LLM) – essentially, an AI with a PhD in common sense – to moonlight as a meticulous project manager. It deftly dissects those infuriatingly vague human commands into a series of bite-sized, achievable sub-tasks, then wraps them in a deliciously ‘dense reward structure’ to keep our metallic apprentices diligently on task. The result? A shiny new Recognize-Sense-Plan-Act (RSPA) pipeline that has seen success rates on notoriously tricky ’long-horizon’ tasks rocket by a dramatic 29.23%. That’s not just an improvement; it’s the difference between a robot staring blankly at a flat-pack manual and actually assembling a functional bookcase.

For too long, the bane of long-horizon robotics has been the dreaded ‘sparse reward’ problem. Imagine trying to learn to bake a soufflé, but only being told ‘good job!’ after the final, perfectly risen result – with no feedback on the egg separation, the whisking, or the oven temperature. Robots faced a similar existential crisis, often only discovering success (or catastrophic failure) after a dozen intricate steps, leaving them utterly bewildered as to which precise actions actually mattered. RoboHorizon, however, sweeps in with a solution so elegantly simple, it’s almost cheeky. Its LLM maestro crafts a meticulously detailed checklist, complete with granular rewards for each individual step. It’s like giving the robot a Michelin-starred recipe, complete with a pat on the back for every perfectly chopped onion.

This cleverness is then paired with a “keyframe discovery” method, which is essentially a robot learning to pay attention. It helps the robot’s visual system home in on the absolute critical moments of a task – think the exact millisecond a gripper lovingly embraces an object, or when that elusive screw finally aligns. It’s the robotic equivalent of not getting sidetracked by cat videos and actually reading the flat-pack instructions before you start wielding the Allen key.

And where did this newfound robotic prowess truly shine? On the FurnitureBench benchmark, of course – a devilishly clever series of IKEA-inspired assembly tasks specifically engineered to push autonomous systems to the brink of mechanical frustration. This gauntlet demands long-term planning worthy of a chess grandmaster, manipulation so precise it could thread a needle, and the uncanny ability to correctly connect disparate parts – challenges that, until now, have left many a cutting-edge model in a heap of metaphorical sawdust. RoboHorizon’s triumphant performance here isn’t just a win; it’s a seismic shift. It heralds a significant stride towards robots capable of handling the precise, complex, and often soul-destroying real-world assembly tasks that have, until this glorious moment, been the exclusive – and frankly, rather painful – domain of us mere mortals.

Why is this important?

This groundbreaking research doesn’t just nudge the needle; it tackles a fundamental, foundational barrier to birthing truly useful, genuinely general-purpose robots into our world. By seamlessly integrating the ethereal, abstract planning prowess of Large Language Models with the gritty, physical execution demanded by a robotic world model, RoboHorizon delivers nothing less than a blueprint for machines that can reliably, even cheerfully, complete chores of dizzying complexity. No longer are our silicon-brained friends relegated to mind-numbing single, repetitive actions. This ingenious approach flings open the doors to a future where robots can plan, adapt, and flawlessly execute multi-stage jobs – be it in the bustling heart of a factory, the sterile calm of a lab, or even the blissful chaos of our own homes. It’s not just a step; it’s one giant, perfectly coordinated leap closer to the utterly competent, perhaps even charming, robotic assistant we’ve all been dreaming of.